Creating Advanced Sensors through Additive Manufacturing

WORKING UP A GOOD SWEAT DURING EXERCISE IS A GREAT WAY TO STAY HEALTHY and provides a sense of accomplishment. However, most people are unaware that sweat also holds vital information about human health, providing clues to dehydration, fatigue, blood sugar levels and even serious conditions such as cystic fibrosis, diabetes and heart failure.

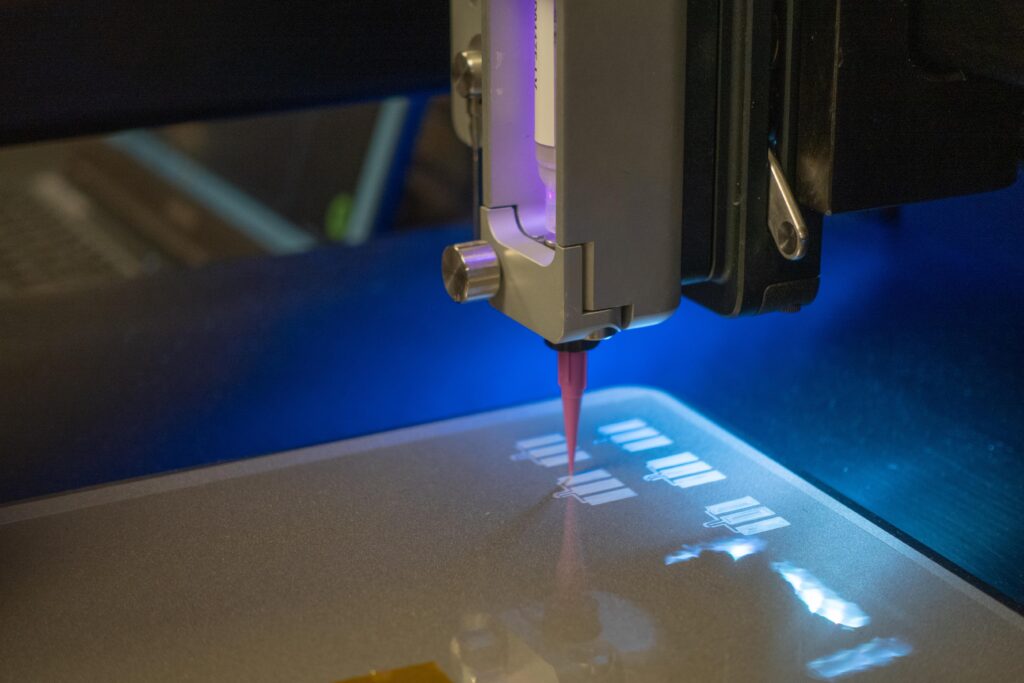

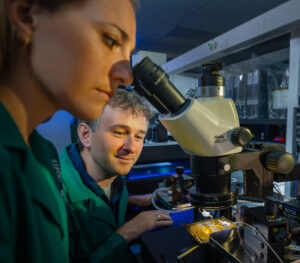

Because of the numerous health signatures that can be obtained from sweat, Mechanical Engineering Assistant Professor Tyler Ray from University of Hawai‘i at Mānoa College of Engineering and his student researchers have developed an innovative 3D-printed wearable sweat sensor called the “sweatainer,” which represents a giant leap forward in sweat analysis.

“The sweatainer is a small, wearable device similar in size to a child’s sticker that collects and analyzes sweat, offering a glimpse into the future of health monitoring,” said Ray, a leading researcher in the field of additive manufacturing (3D printing), with a particular emphasis in healthcare. “By incorporating various sensors, the sweatainer can analyze sweat in a mode similar to previous wearable sweat-sensing systems.”

Efficiency and cost-effectiveness are the advantages of Ray’s device. Traditional methods for sweat collection use absorbent pads or microbore tubes pressed against the epidermis using bands or straps to capture sweat as it emerges from the skin. These techniques require trained personnel, special handling and costly laboratory equipment. The recent emergence of wearable sweat sensors has addressed some of these challenges, but these devices still remain single-use.

A unique feature of the sweatainer is its “multi-draw” sweat collection method, which allows for the collection of multiple, separate sweat samples for analysis either directly on the device or sent to a lab. Inspired by the vacutainer used in clinical blood sampling, this advancement not only makes sweat collection more efficient, but also opens up new possibilities for at-home testing, storing samples for future research, and integrating with existing health monitoring methods.

“3D printing enables an entirely new design mode for wearable sweat sensors by allowing us to create fluidic networks and features with unprecedented complexity,” said Ray.

“Through the blueprint established through the sweatainer and other technologies like wearable ring sensors, we are hopeful that this will continue to drive innovation to create a future where personal health monitoring is more accessible, convenient, and insightful.”

– Tyler Ray

In 2021, Ray and researchers from Northwestern University developed a cutting-edge skin-mounted sticker to diagnose cystic fibrosis, one of the most common life-shortening genetic disorders. The novel wearable device absorbs sweat and then provides a simple, accurate diagnosis within minutes using a color changing sensor.

The concentration of chloride in sweat is the most robust biomarker for a positive diagnosis of cystic fibrosis. Previous leading methods used a hard, rigid, wrist-strapped device. Ray’s research team developed a soft, flexible sweat sensor that is both comfortable and imperceptible to the wearer, enabling the sticker to collect 33 percent more sweat than the current clinical method and ensuring that one test will consistently provide a sufficient sample for an accurate diagnostic result.

The sticker also incorporates built-in colorimetric sensors that detect and measure the chloride concentration using a smartphone camera in real-time. This integrated analytical capability eliminates the need for expensive laboratory equipment and lengthy, emotionally challenging wait times. This opens the possibility for testing in locations lacking access to certified cystic fibrosis testing facilities, as is the case for most Hawai‘i residents.

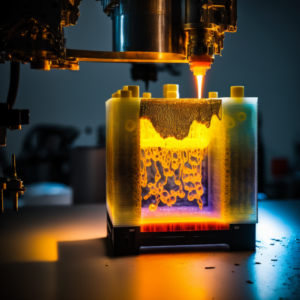

In 2022, Ray received a two-year, $237,916 grant from the National Science Foundation (NSF) to explore innovative fabrication techniques to create high-capacity batteries in many different areas, including healthcare. With this grant, Ray aims to address the challenges currently faced in the production of silicon nanoparticle electrodes, a promising material for high-capacity batteries with applications in industries such as electric vehicles, power systems and medical devices. The project seeks to develop a scalable and robust method of manufacturing silicon nanoparticle electrodes, with the ultimate goal of advancing battery technology through the use of additive manufacturing. Ray will work closely with Distinguished Professor Ram Seshadri at the NSF-supported Materials Research Laboratory at the University of California, Santa Barbara, one of the top five materials research facilities in the world.

Last summer, Ray became the first researcher from Hawai‘i to participate in the 28-year history of the National Academy of Engineering’s The Grainger Foundation Frontiers of Engineering program. In June of this year, Ray received the prestigious NSF Career Award for his work in additive manufacturing, becoming the first faculty member from UH Mānoa’s College of Engineering to receive this honor since 2016.