An Innovation That Could Transform the Food Industry

Imagine reaching into the freezer to prepare a meal. The frozen chicken breast remains pliable and fresh, the frozen blueberries and strawberries for dessert thaws without turning mushy. Although it may sound like a futuristic scene from Star Trek, think again.

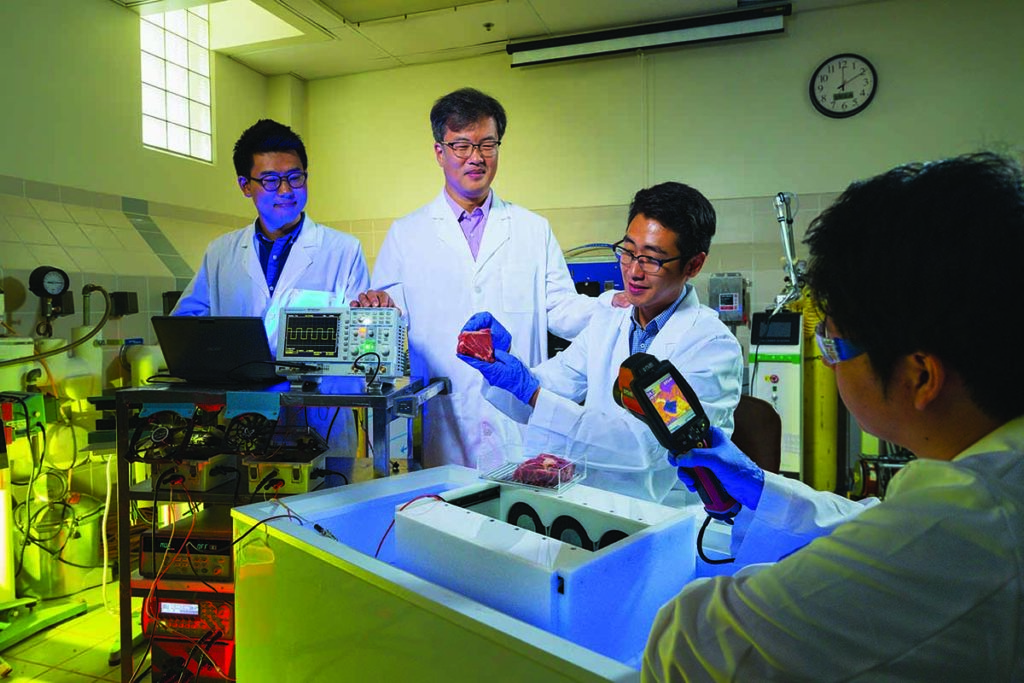

It’s the Food Processing Laboratory at UH Mānoa’s College of Tropical Agriculture and Human Resources (CTAHR) and the technology is a promising supercooling method—which combines pulsed electric and magnetic fields to reach subzero temperatures without turning liquids solid.

In 2013, Soojin Jun, an associate professor in CTAHR’s Department of Human Nutrition, Food and Animal Sciences (HNFAS), received a three-year $500,000 grant from the USDA to study a high-tech new way to preserve food for storage and shipping. Along with Co-Principal Investigator Peter Berkelman, an associate professor in the UH Mānoa College of Engineering, the duo embarked on a research project to address the loss of quality in food items due to freezing and thawing during storage and transportation, which leads to waste and a decrease in economic value.

During the freezing process, water crystallization can result in irreversible damage to tissue structures resulting in damage to a variety of foods. In contrast, Jun’s project aimed to preserve food’s original freshness by controlling the supercooling and ice crystallization of water using combined pulsed electric and magnetic fields. “Supercooling” refers to the process by which water temperature drops below the freezing point, but there is no transition to ice. “Imagine supercooled sashimi that tastes as fresh as it did out of the sea four weeks ago,” said CTAHR’s Associate Dean for Research Ken Grace.

A portion of the grant included the development of a prototype freezer equipped with pulsed electric field and oscillating magnetic field generators, designed and fabricated in the HNFAS lab. This technology has the potential to ensure food quality and freshness during storage, which would have an enormous impact on the food industry. It would specifically benefit Hawai‘i and the Pacific Basin by ensuring food security and sustainability, as well as provide new export opportunities for local farms and entrepreneurs.

According to Grace, “supercooling isn’t just applicable to the food industry either. The possible medical applications for organ transport and long-term blood storage are bringing attention to Dr. Jun’s work too.”

Last year, Jun’s supercooling technology spinout (inventions developed from university research) Jun Innovations, was invited to present at the prestigious First Look LA showcase of university technologies at UCLA’s California NanoSystems Institute. Over 250 investors and entrepreneurs were in attendance at the invitation-only event. Jun Innovations is a graduate of XLR8UH, UH’s proof of concept center/venture accelerator program. Success continues to follow Jun Innovations, as the promising spinout was recently awarded with a USDA SBIR Phase 1 grant for $100,000 on June 1, 2016.

Beyond the food industry, the supercooling technology has exciting possibilities for use in medical applications such as organ and tissue transplantation. It also just one of many technologies explored by Jun’s Food Processing Laboratory.

His lab also developed a patented technology that combines ohmic heating by electric current (efficient for liquids) with microwave heating (good for solids). Current methods for foods such as soups require heating components separately, which is inefficient, or else overheating solids, which degrades quality and nutrition. He sees similar potential for companies processing local foods like poi and kava.

Supported by more than $2.5 million in USDA, industry and international grants since 2008, Jun’s team also researches pathogen-fighting technologies such as laser decontamination of fresh produce and nano-material coatings to reduce bacteria-promoting biofilm buildup on the surfaces that come in contact with food during processing. He would also like to explore biodegradable or edible films as waste-reducing packaging.

“I’m not a just foodie guy,” Jun insists—an electrical/agricultural engineer at heart. “There are so many things you can do as an engineer.”